Alpha Converting is a manufacturer and supplier of slitter rewinders, unwinds, rewinds and spooling equipment for the converting industry. Equipment is made to the highest standards and our engineering expertise is second to none within the converting field.

Products converted on ALPHA machines include flexible packaging, films, foils, tapes, label stock, laminates, paper and nonwovens.

Slitter rewinders

The twin shaft ALPHATWIN is a very flexible slitter rewinder with two cantilevered rewinding shafts. It offers precise control of winding conditions with excellent flexibility and productivity giving consistent output time after time.

Standard features include swing away shaft supports on the wider machines for quick roll change, closed-loop unwind tension control and operator touchscreen. The integrated recipe system allows the operator to create, store and recall product recipes for consistent winding quality.

Options include the class leading automatic knife setting system, laser core positioning and powered roll stripping and unloading.

Single head and multi-head spoolers

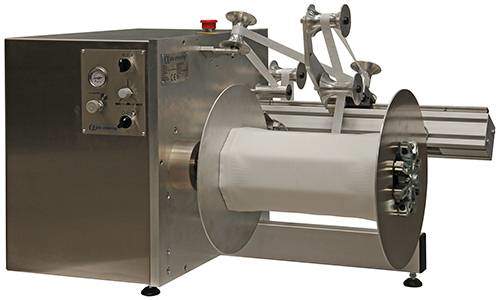

The free-standing ALPHASPOOL RSM is a standalone spooler for converting pancake rolls to spools. Ideal for small batch production or lower volume markets, the spooler can also be used for winding spool to spool.

Alpha offers a choice of slitter spoolers for slitting and spooling in one machine. The unwinding and slitting section is configured to provide fast roll change and accurate slitting to suit customer requirements.

Spooling heads can have independent control for individual units, or the ALPHASPOOL-6 modular spooling system can be used with six heads working together for a more cost-effective solution.

Automatic winders for rapid roll changes of packaging materials

The fully automatic ALPHAMATIC winder delivers rapid roll changes for a variety of materials. The servo controlled rewind operates with centre drive technology to provide precise control for winding of sensitive products. For most processes, roll attachment to the core is fold free without tape.

Inline systems are available with nonstop operation. Standard options include slitting, automatic core loading, label closure, bagging and printing.

Unwinds and rewinds for packaging

ALPHAREEL unwinds and rewinds can be supplied for integration with any process. They can be supplied standalone or fully integrated. Each winder has precise tension control. Configured for unwinding or rewinding, shafted or shaftless, ALPHAREEL winders can be supplied for web widths from 50mm to 3,000mm.

Wind edge trim winder with noise reduction and boosted recycling

ALPHATRIM traversing winders wind edge trims for a wide range of applications. The spools can be wound on paper cores or a coreless quick release chuck. Each trim winder has closed-loop tension control and can be put into production without the need for integration with the process line.

Edge trim winding on an Alpha winder offers reliability, noise reduction and improved recycling, with return on investment down to six months.

Salvage rewinder

The ALPHASAVE salvage rewinders can be used to doctor poorly wound reels, or joining and splicing part length rolls. The machines have precise programmable unwind and rewind tension control, with recipe storage for quick and easy recovery of damaged or sub-quality rolls.

About Alpha Converting

Alpha Converting is a flexible company based in the UK, producing high-quality equipment for the converting industry worldwide. We look at each application individually to provide customers with the best solution.

If there is not a standard solution for your production requirements, we will develop a new solution that is right for you with a team of expert engineers and a strong history of innovation.