MET-LUX specialises in the vacuum metallisation of a variety of flexible materials. We metallise substrates for food packaging, holographic and printed films, cardboard lamination, buildings insulation and other applications.

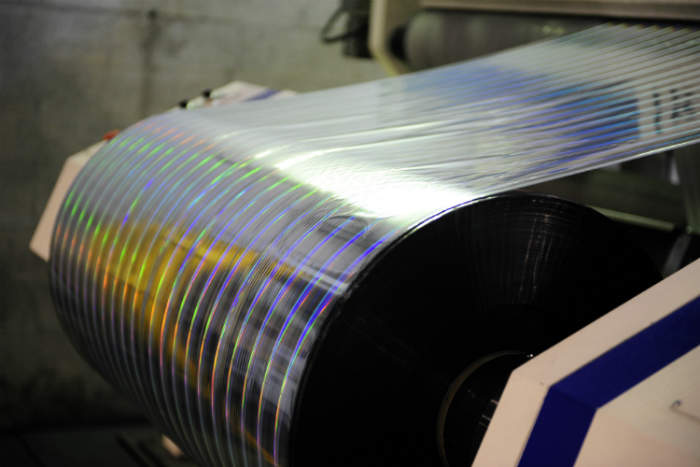

We have five metallisers and seven slitters at our production facility, plus additional equipment such as plasma treatment and visual inspection systems, which provide a guarantee of quality for our customers, particularly for specialist applications.

Metallising films for food packaging

Our core business sector is food packaging and we metallise a wide variety of films for different uses in this area. Our range includes the main film types OPP, PET, LDPE, HDPE, BOPA, CPP, and PLA.

Based on requirements, the optical density level can vary from the lowest for packaging for use in microwave ovens, to the highest for bag-in-box packaging. We also offer a range of products specifically for labelling.

Holographic and printed films / cardboard lamination

We supply a complete range of metallised products for lamination onto a variety of media, such as cardboard, for use in the luxury goods market.

Metallised matte or glossy OPP, PET or PE films can be provided as required. Films can be printed or coloured in the mass to provide different colours, such as gold.

These films generally vary in thickness between 8µm and 23µm, with 12µm being the thickness currently most widely available on the market.

As the product’s main function is aesthetic, these films are generally metallised on one side only, to standard optical density

Films for insulation and barriers

New, multi-layer insulating structures appeared on the market a few years ago. For the same thickness, they offer better insulation performance than, for example, traditional polystyrene-based products. These structures comprise a number of layers of different materials, including metallised film layers with infrared reflective properties.

These applications use a number of different types of film, particularly PET and PE, which can be metallised on one side or both if needed.

A commonly used structure is expanded polystyrene structure laminated with metallised polyester film, which improves the product’s insulation performance.

Non-woven, largely polyethylene fibre-based films are also metallised and incorporated into structures used in the construction industry, introducing humidity barrier properties and strengthening the insulation performance of the structure by reflecting infrared radiation.

The following is a basic list of the films that we offer, which are commonly used in insulation:

- Plain or corona-treated 8µm to 12µm PET, metallised on one side or both to standard optical density

- 35µm LDPE metallised to standard optical density

Metallisation of solar textiles

Metallisation is used in the solar textiles market for its reflective properties. The use of metallised window shades to reflect light considerably reduces the amount of heat transmitted into buildings on sunny days.

The films help control the temperature inside the building, limiting the use of air-conditioning and resulting in considerable energy savings. These shades can be fitted inside and outside, with those fitted externally having the greatest effect. One or both sides of the product can be metallised.

With a wealth of experience in this business sector, MET-LUX is an indispensable partner for all your PET, glass fibre / PVC or OPP-based textile metallisation projects.

Please contact us using the enquiry form below to send us your business enquiry.