Jongerius Hanco BV is an established manufacturer of multipackaging systems for the secondary packaging industry worldwide. The company supplies multipackaging machines that help optimise production operations.

Jongerius Hanco uses bag-in-bag packaging to produce a bundle pack where the single pouches are neatly aligned. Jongerius Hanco BV works closely together with customers and uses its knowledge and expertise to translate their questions and problems into clearly thought-out, customised solutions.

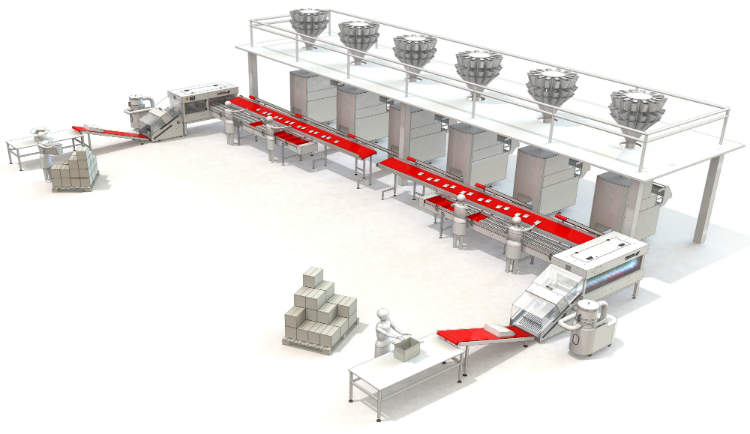

The company supplies fully automated and semi-automated secondary packaging machines, as well as a range of machines for the secondary packaging process to create variety packs. Moreover, Jongerius Hanco BV offers additional services, such as installation of its machines on-site and training of personnel when needed.

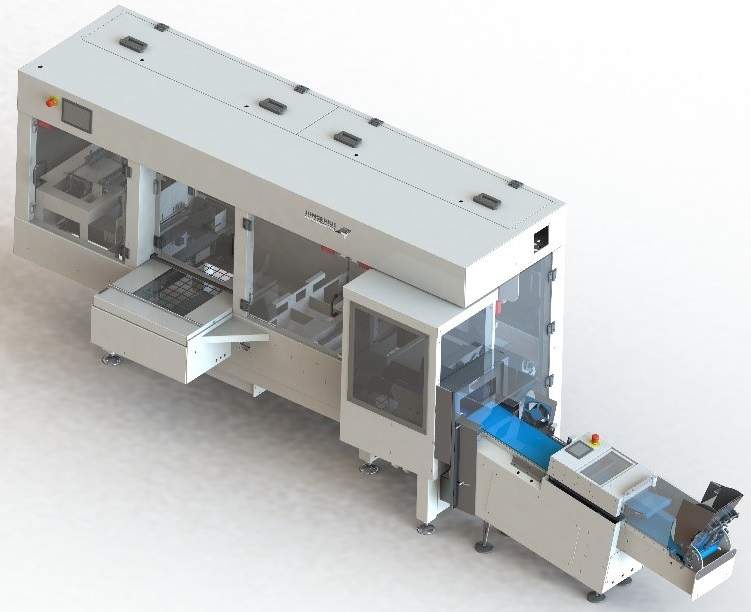

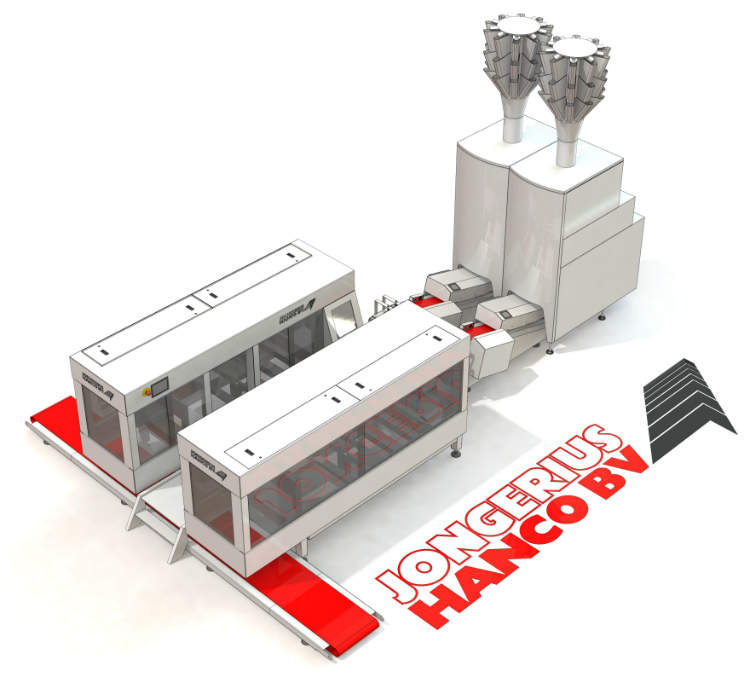

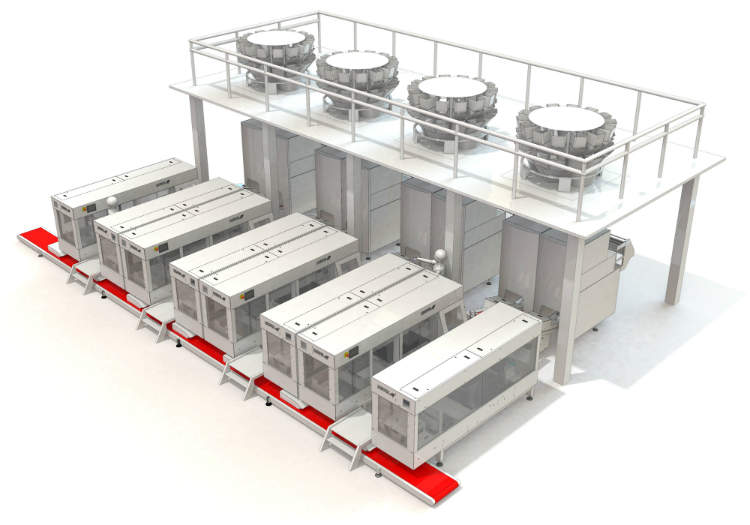

Aligning collating multipackaging machines (ACM) for fully automated operations

The Aligning Collating Multipackaging machine, or ACM for short, is the newest development by Jongerius Hanco. This fully automated packaging machine handles pouches straight from the Vertical Form Filling machines (Vffs or Bagmaker) without human interaction.

The Aligning Collating Multipackaging machine produces multisacks with multiple rows of pouches within one multisack. The desired configuration of pouches is pre-determined and entered into the ACM OIT screen as an SKU. The ACM collects the pouches in the required pattern and pushes them into a waiting, inflated polysack that is sealed by an integrated sealer, then drops to await shipment.

The ACM can handle up to 120 pouches a minute from the Bagmaker, dependent on the pattern and weight of the pouches.

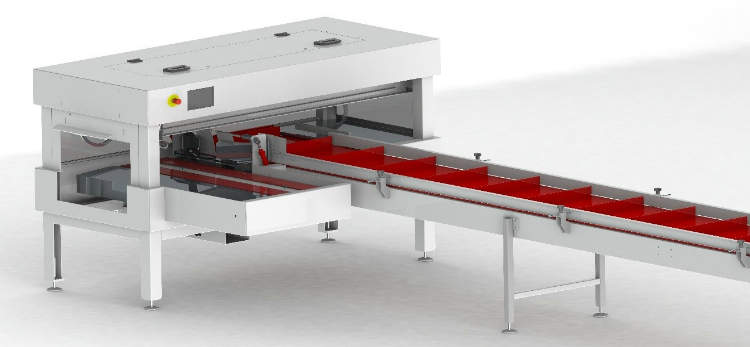

Aligning collating multipack machines (ACM) for production of multisacks and variety packs

The ‘in LINE’ version of the ACM produces multisacks with one single line of pouches. The process is similar to that of the ‘standard’ ACM, with the desired number of pouches within multisacks entered into the ACM OIT screen as an SKU.

The required number of pouches is collected and pushed into a waiting, inflated polysack, which is sealed by the integrated sealer and then drops from the ACM. This type of ACM can process up to 120 pouches from the Bagmaker in a minute.

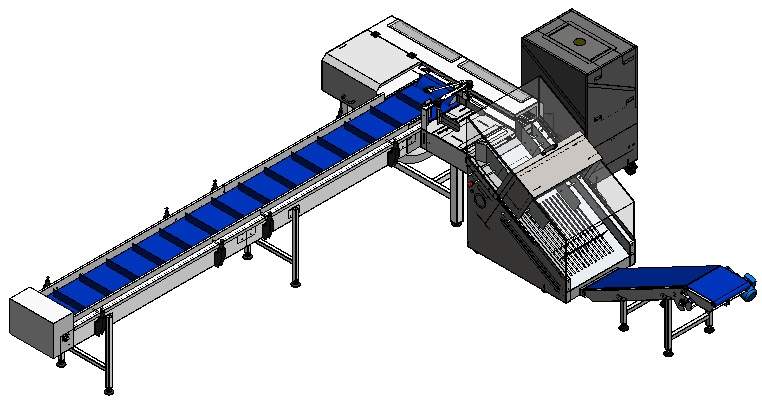

Bag inspection solutions with seal testing capabilities

The Jongerius Hanco Bag Inspector is situated between the Bagmaker and the ACM machine to ensure only pouches with a high-quality pass into the ACM. The Bag Inspector functions as a normal seal tester, able to perform multiple measurements on pouches as they travel through the Bag Inspector and any leaks in the seal are detected.

However, the Jongerius Hanco Bag Inspector has several additional functions, with pouches with a too high or too low air fill rejected and blown from the Bag Inspector, double and empty pouches are detected (and rejected) and it can even repair faulty pouches. Up to 120 pouches can be inspected in a minute.

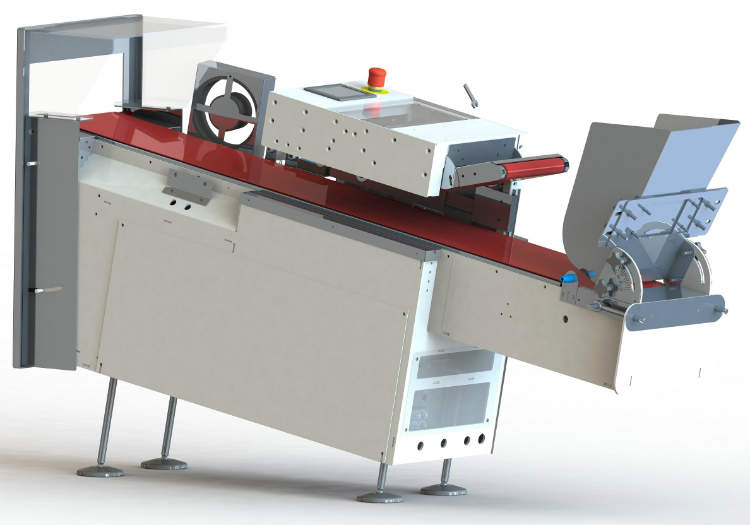

Semi-automated multipackaging machines

The Speedpack II is one of the semi-automated secondary packaging machines designed by Jongerius Hanco. Pouches are manually placed into the Speedpack II conveyor belt that is divided into ‘pockets’ by cleats (cleat distance is client-specific). Workers organise the pouches within the ‘pockets’ into the desired pattern. A double pusher arm mechanism then pushes the entire contents of the ‘pocket’ into a waiting, inflated sack that drops from the machine when filled.

The Speedpack II can produce up to 30 multisacks a minute, depending on the type and size of the product.

Bundling by the Multipack takes place in the same way as the Speedpack II. However, whereas the Speedpack II has a double pusher arm mechanism, the Multipack has a single pusher arm mechanism.

The Multipack machine has a production of 15 up to 18 multipacks a minute, depending on the type of product and polysack.

Sack sealers, trimming and waste suction units

The semi-automated packaging machines do not have a built-in sealer. However, Jongerius Hanco supplies a solution for this as well in the form of the Gravity Impulse Auto (GIA) Sealer. The GIA Sealer is placed on the output end of the Multipack or Speedpack machine. Filled multisacks drop into the GIA Sealer and the sack is sealed shut.

Both fully automated packaging machines and the GIA Sealer can be combined with a Trimming and Waste Suction Unit. This machine cuts of the excess sack after sealing and removes it to avoid machine clogging.

Automated packaging advantages and machine design

Due to time and experience Jongerius Hanco can confidently state that the change from manual to semi-automated multipackaging can save you between 50% and 60% in labour costs. Moreover, using a semi-automated multipackaging system increases continuity of production and will ensure product handling is neat and clean.

The Jongerius Hanco packaging machines are manufactured using exclusively high-quality parts from European suppliers. Fully automated packaging machines are equipped with servo motors, are PLC-controlled and operated through a state-of-the-art OIT touchscreen.

The chances are that Jongerius Hanco has the solution to meet your packaging production needs. To find out more, use the form on this page to send an enquiry.