UPM Specialty Papers’ oneBarrier FibreCycle packaging is said to provide a sustainable, recyclable, paper-based alternative to the multi-laminate plastic structures used for long shelf-life products such as food.

The company plans to showcase its new product at the Interpack exhibition which is taking place in Dusseldorf on 4 to 10 May 2023.

UPM Specialty Papers explains that its oneBARRIER FibreCycle can be recycled in existing fibre recycling streams, which allows brand owners to reduce their reliance on fossil-based, non-recyclable materials.

“This is a truly ground-breaking solution for foods with a long shelf-life. These products are usually packaged in a variety of plastic laminates or plastic structures that are not recyclable. Our aim was to produce a recyclable, paper-based packaging solution – and we can say ‘mission accomplished’. Now we’re delighted to offer Interpack visitors a closer look,” says Janne Varvemaa, director, products & technology at UPM Specialty Papers.

Paper-based packaging for coffee, spices and other challenging end-uses

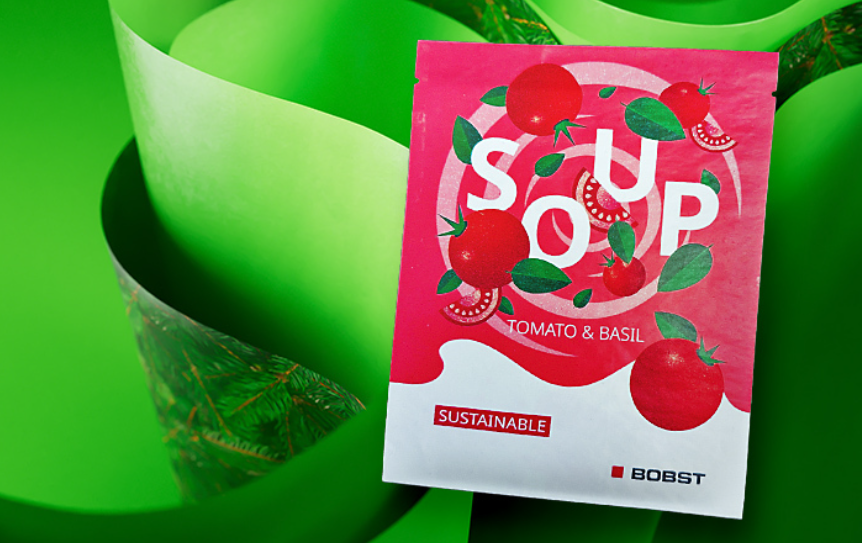

One Barrier FibreCycle is the result of a collaboration between UPM Specialty Papers, print equipment specialist Bobst and coatings firm Michelman.

Bobst marketing and communications manager, Sara Alexander points out: “Recycling is a must for any new packaging solution coming to the market. We can be proud of having accomplished that with an elegant, lightweight solution that is ready for commercial use.”

To create the paper-based alternative, UPM Specialty Papers explains that its Solide Lucent offers a dense, smooth, and strong bases paper, which is ideal for lightweight and uniform coatings. Meanwhile, Bobst provided the AluBond technology – an aluminium coating about one-thousandth the thickness of human hair and Michelman supplied the integrated coating system that gives barrier properties, priming and heat seal.

These solutions together are said to result in an innovative approach to safeguarding food products with a long shelf-life such as coffee, instant soup, sauce powers packets, spices and milk powders.

Sales director of EMEA at Michelman, Thierry Van Migem, added: “It is especially important to stay agile in the face of continually evolving legislation. By incorporating the highly versatile barrier properties provided by advanced coating technologies, we have been able to meet the performance needs and sustainability goals that are prevalent in the market.”