Managing director of specialist wet wipe and sachet manufacturer Guardpack, Jeremy Freedman, shares an in-depth look at contract sachet filling and its associated benefits.

Contract sachet filling – the process of a manufacturer filling a company’s liquid products into sachets – is becoming increasingly popular across many industries.

Cost-effective, convenient and used across a range of sectors – from industrial products to cosmetics – sachets allow businesses to provide their customers with the opportunity to purchase products in smaller quantities. Further to this, massive benefits can be found in sachet marketing and with countless brands and manufacturers pushing for more sustainable practices, there’s no longer any reason for these single-use products to damage the environment.

Why use sachets for packaging?

Simply put, sachets are incredibly useful for any product that benefits from being single-use, in small volumes. Sun creams and hand sanitisers, for example, are well-suited to sachets, especially when used on the go.

The size of the sachet makes them convenient in regards to portability, with customers only needing to carry a few at a time. Ideal to be kept in handbags, the glove compartment of a car, pockets, or anywhere else where a full bottle isn’t needed.

Furthermore, sachets are also incredibly resilient. Airtight and unlikely to be compromised in any way, leaks won’t be a concern and any product with a short life span after being exposed to air won’t be at risk of ‘going off’. Despite their resilience, however, they are very easy to open via the tab and remain discreet and mess-free after use, until they can be disposed of appropriately.

Sachet sampling

The fact sachets are small, flexible and lightweight is not only beneficial for the customer carrying them around, but also for those distributing them. They take up almost no space when individually packaged with other products or inside magazines; one of the many reasons sachet sampling is such an excellent marketing technique. A method widely used in the cosmetics industry in particular; sachet marketing is an effective promotional activity in any setting, from a store counter to a trade show.

Perfect for products that typically come bottled – such as eye creams, facial oils and body lotions – liquid-filled sachets – manufactured using foil, plastic, paper or recyclable film laminate, subject to testing – provide potential customers with a metaphorical taste of the product.

In fact, a study by Arbitron found that over a quarter (26%) of those who previously hadn’t heard of a sampled product went on to buy it, and of those who had heard of the product, a fifth of them went on to buy it after sampling. Other reports have determined that as many as 73% of consumers would be likely to purchase a product upon sampling it. Further to this, Marketing Journal has claimed the effects of free samples have been shown to impact customer purchasing intent for a remarkable 52 weeks after receiving the sample.

The contract sachet filling process

The contract sachet filling process will undoubtedly shift between companies, but any manufacturer like Guardpack can be expected to deliver a similar range of services within a product’s manufacturing process – from the design stage to ensuring the product is retail-ready.

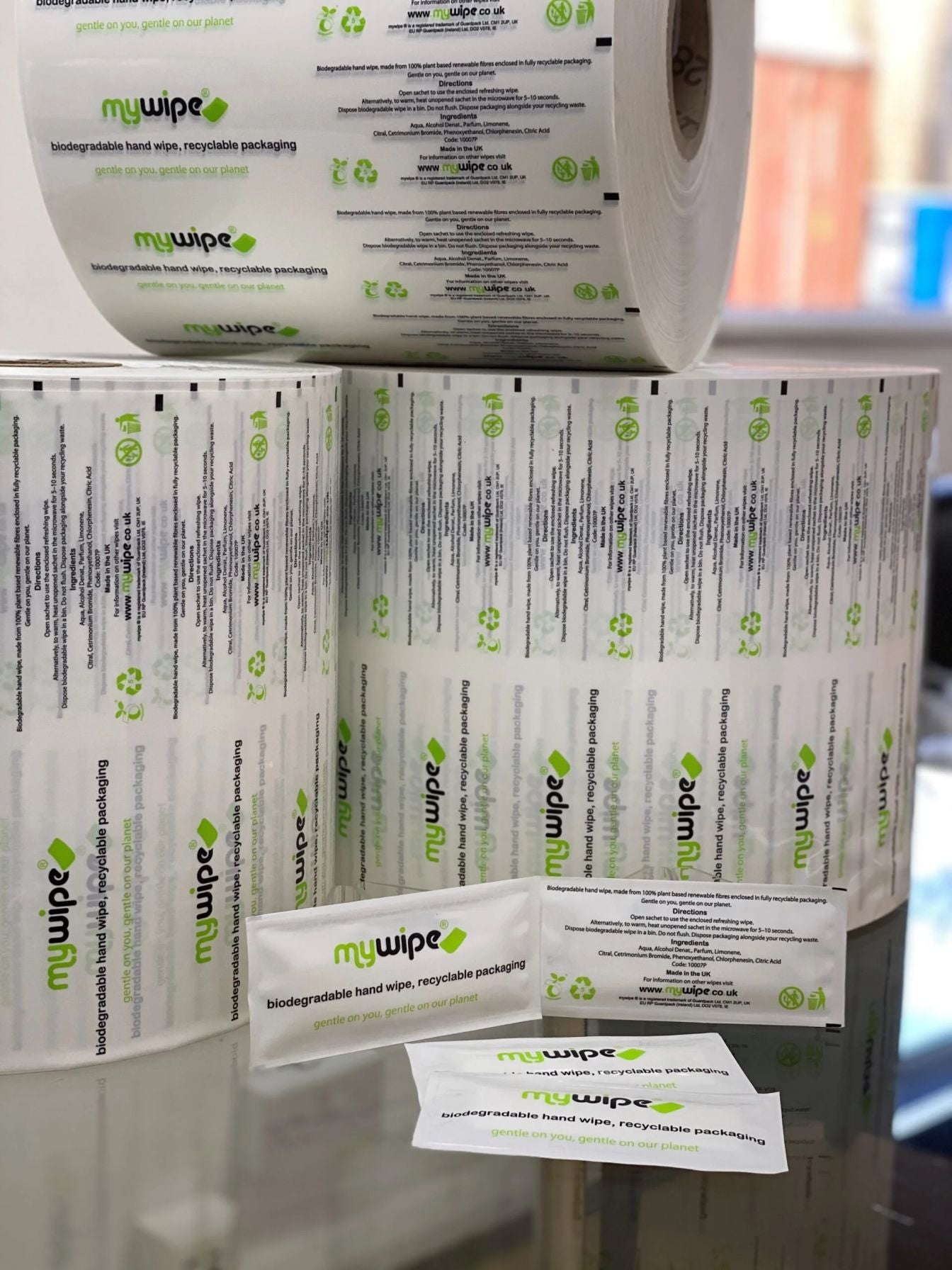

Deciding on the size/volume of products, as well the preferred sachet material, is the first step. From aluminium-lined or microwavable sachets to the recommended biodegradable ones, there is a wide range of options, often dependent on the product. Sachet sizes generally range between 50mm x 50mm to 140mm x 150mm and hold between 1ml to 40ml, with many manufacturers utilising pumps accurate to a tolerance of 0.1ml.

The product may then need to be tested to ensure its compatibility with both the manufacturing machines and chosen sachets. This is unlikely to be essential, but if in doubt, the manufacturer may need to carry out a check.

Once the product is confirmed to be viable for the manufacturer, a final design will need to be reached. Some manufacturers will have a network of creative designers to hand for this very reason. Others may simply require the brand logo to create the final design themselves. Either way, printing and cutting guides for a manufacturer’s machines should be available to the client, in order to make the design process easier. It’s also essential that packaging covers any regulatory information that has to be included by law.

Once volume, material and design has all been confirmed, it will be down to the manufacturer to print the designs and fill the sachets. Following this, there may be the option to either send the loose bulk to the client, following a quality check, or secondary pack the sachets, in either generic boxes or bespoke packaging, ready to be sent straight to the retailer.