Tone Product Design co-founder and managing director Oscar Daws explains how working with packaging designers from the inception stage, medical device manufacturers can improve the patient experience.

Anyone working in the world of packaging will appreciate the many roles it has to play, whatever the sector. However, when it comes to medical packaging, there’s an opportunity for designers to extend that role beyond the obvious considerations – protection, tamper-proofing, sterilisation, etc – and leverage the packaging to form part of the product itself.

We know that with pharmaceuticals and healthcare there are all kinds of safety considerations and strict guidelines about how information is presented. But the packaging will be the patient or end-user’s first touchpoint when it comes to interacting with a product, so it can play an important role in how they respond and relate to it.

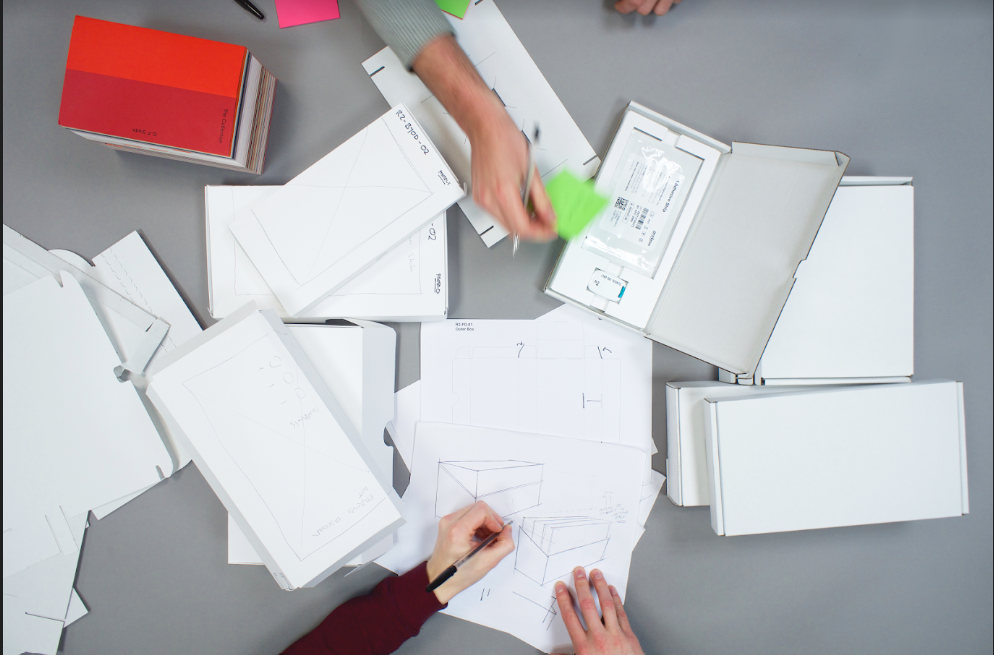

If packaging is considered by medical device designers from the outset, they can explore the role packaging can play more fully, and maximise the opportunity to improve the patient or end-user experience – as well as conform to all the necessary regulations.

Then, of course, there are the brand messaging considerations, measures to encourage adoption by the end-user, adherence and safety, especially as medics and caregivers increasingly encourage people to look after themselves at home without the help of a professional (Covid-19 testing is a good example of the home-administering shift). But all too often, the opportunities to improve the patient experience via packaging are overlooked.

When the product and its packaging are designed together from the get-go, there is a chance to fully break down and curate that initial experience, to hold the end-user’s hand through the process, improving adherence, boosting safety and making the whole experience more positive and less worrying or confusing.

Helping navigate the journey

A lot of medical packaging specialists use hierarchical task analysis to help us map out the exact journey we want the end-user to take from the moment they receive the package. Then we use perception, cognition and action analysis to look into individual tasks and work out what the end-user should ‘perceive’, what they need to ‘understand’ and what they’d ‘do’ next. All of this works to expose opportunities for design to improve the experience and lessen risk.

This process also informs many of the creative decisions packaging designers need to take, such as choice of images and colourways, information hierarchy and even fonts. We look at ways to express the brand messaging in the best light, too, but we do all this while constantly prioritising the patient or end-user experience.

For digital products, including wearable devices or apps that require on-screen onboarding, the role of packaging might be geared towards expressing brand attributes such as quality and encouraging the user to engage with the digital experience. For other products, however, especially medical devices or drugs, there might be safety-critical information that needs to be understood, self-assembly required, or complicated use sequences. This is where the packaging specialist can elevate the experience for the brand and the end-user – but it needs to be considered in tandem with the product or device development phase to work.

Giving patients and end-users the power

When we created the pack for Proteus, the first FDA-approved ingestible sensor and wearable device that allows healthcare practitioners to monitor drug compliance remotely, a key focus of the design was to make it easier for patients to set up at home. This was achieved with a thoroughly considered step-by-step unboxing experience and straightforward, persuasive content created to reduce confusion.

Previously the onboarding process required the presence of a trained healthcare professional. Our aim was to make Proteus work in a home-onboarding environment. To achieve that, we focused on using the packaging to convey clear instructions and messaging, and on making the experience as pleasant as possible for the patient – with special consideration given to patients with limited dexterity. An added effect was that it rendered it more commercially scalable, too.

Remembering the human element

As medical packaging and product designers, it’s important to remember the human being at the end of the chain. Every part of the system should work as hard as it can to reduce the cognitive and physical burden on the patient and improve the overall experience. We don’t want to embarrass people, confuse them or have their health deteriorate.

As home-based healthcare and patient monitoring become an ever more critical part of the healthcare value chain, packaging and product design considerations should come together at the start of a project to ensure that all systems tesselate and the end-user has the best experience possible.