Herti is a leader in manufacturing aluminum screw caps, and plastic and composite closures for a wide variety of bottles to be used in the food-processing sector.

The axis of the company’s ethics is creating new ideas related to the company slogan, ‘Your brand tomorrow is our business today’. A public company that has subsidiaries in the UK, France, Germany, the US, and Romania, Herti is a manufacturer of more than two billion screw caps annually. These come in 40 sizes and are sold in over 50 countries worldwide.

The company can manufacture virtually every aluminum closure dimension and advise clients on packaging services for wine and spirits, non-alcoholic drinks, olive oil and pharmaceuticals. Herti makes available aluminum caps with a diameter ranging from 17mm to 43mm and height from 12mm to 60mm. These are utilised as a sealing solution for bottles with multiple uses, varying from 50ml to a gallon (4.54l). Herti offers clients possibilities through a wide range of sizes and shapes so that clients can create the best packaging for their needs and brands.

Herti offers a variety of options relating to printing and finishing, up to five colours of offset printing, mat, semi-mat and glossy finish, hot-foil printing, embossing and shaving, and top relief. There is also the option of choosing different liners for different brands, such as EPE liners with different densities, SARANEX and TIN liners, compounds, and non-refillable pourers.

Herti collaborates closely with clients throughout all stages of product development and offers customised design and high-quality end products.

Herti’s management supports new product development and originality for clients globally. The research and development (R&D) department under the Technical Division aims to make new product processes more functional, boost the study of new materials and technologies, and promote improved products throughout production. The company’s management also puts into effect technological and organisational advancements in the workplace. This enhances Herti’s place in the competitive market and foregrounds the company’s sustainable mission and customer satisfaction processes.

Aluminium closures for bottles

Aluminum closures are an integral part of a bottle’s and brand’s design and presentation. Herti makes available more than 40 closure size types, covering 90% of all aluminum closures on the market.

Closures with the HL sign are delivered with consistent quality to over 50 countries around the world. Quality and safety are the company’s top priorities through strict control of the whole procedure and the use of certified raw materials.

Herti has been ISO 9001 certified since 2000 and has had BRC/IOP accreditation for the Global Standard for Packaging and Packaging Materials since 2010. In 2023, Herti became ISO 14001 and ISO 45001-certified.

Aluminium closures are very often used on spirit bottles. However, closures with dimensions 31.5mm × 24mm and 31.5mm × 44mm with olive oil pourer liners can also be utilised for sealing olive oils, while closures with dimensions of 28mm × 15.4mm plus PVC compound are used for carbonated drinks bottles.

Screw caps for wine bottles

Herti brings forward innovative products that meet the needs of wine producers as well as the worldwide requirement for wine bottles with aluminum screw caps. ‘Vinstar’ is the trademark for aluminium wine closures produced by Herti.

All types of aluminium closures that Herti produces have SARANEX or TIN liners. The most sought-for dimensions for wine are 30×60, 28×44, 30×24,25×43,25×17,22×30, and 22×15.

Aluminium and plastic closures for soft drinks

Herti offers aluminium and plastic closures for water and soft drinks bottles in dimensions such as 28mm x 15.5mm, 30mm x 25mm, PCO; BPF, 48mm x 41mm. The company also produces plastic handles.

The composite closure is the most popular solution for mineral waters and is called DORADO. This is an aluminium closure with a plastic safety ring that is tamper-evident and protects from injuries. This cap is designed for high and middle-class bottles of still and sparkling water. This solution is suitable for ozone and sensitive waters as the compound it uses is PVC-free.

Eco-friendly packaging production

Herti also supports energy efficiency by investing in state-of-the-art technologies.

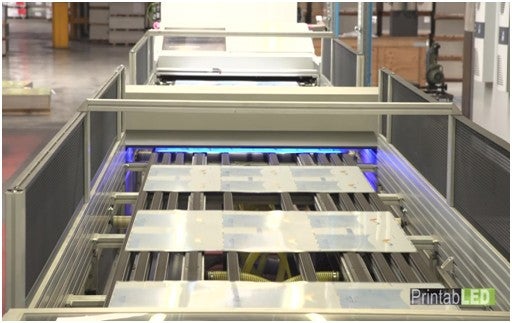

Herti is an environmentally conscious company with a clear aim to use natural resources. In the last years, the company has made significant progress in using green technologies to boost its production process. Herti recently invested in new pioneering technology, the Mailänder 280 by Koenig & Bauer, in order to enhance the print quality of decorative features while reducing its environmental impact. The new line uses UV-LED drying, which is energy-efficient and consumes no natural gas and less electricity, at the same time as it eliminates CO(2), ozone, and heat emissions.

A recent lifecycle assessment study revealed that recycled aluminum uses 95% less energy in comparison with producing primary material. One-third of the aluminum Herti uses in its production is recycled.

Herti is a SEDEX and EcoVadis member and is highly committed to the environment as it continuously reviews its material sources to ensure they are eco-friendly and ethical.

As an Ecopack partner and shareholder, Herti meets all sustainability principles.