BERICAP is one of the leading global manufacturers of plastic and aluminium closures for food, beverage, and industrial applications. With a rich history of innovation, the company has become a trusted partner, offering a diverse range of closure solutions that ensure product integrity, safety, and convenience. BERICAP supports its customers at every stage of the closure selection and development process.

With over 30 production plants worldwide, BERICAP serves customers in more than 100 countries, combining local expertise with a global presence.

Innovative and sustainable closure solutions for packaging

At BERICAP, innovation and sustainability are at the heart of everything we do. Our specialised research and development (R&D) centres and in-house mould shop enable us to design advanced closure solutions that address both current market needs and future challenges. One of our top priorities is sustainability through lightweight closures that reduce material use and incorporate—whenever possible—post-consumer Recycled (PCR) materials, supporting a circular economy.

Our commitment to sustainability extends to all aspects of our operations. We continually invest in technologies that reduce energy consumption and waste, ensuring an eco-friendly production process. Additionally, our closures feature innovations like the patented DoubleSeal™ system, which offers superior sealing and Flow Control closures, providing precise, drip-free pouring. By focusing on sustainable design and performance, BERICAP helps brands achieve their sustainability goals while delivering high-quality solutions.

Quality and reliability across industries

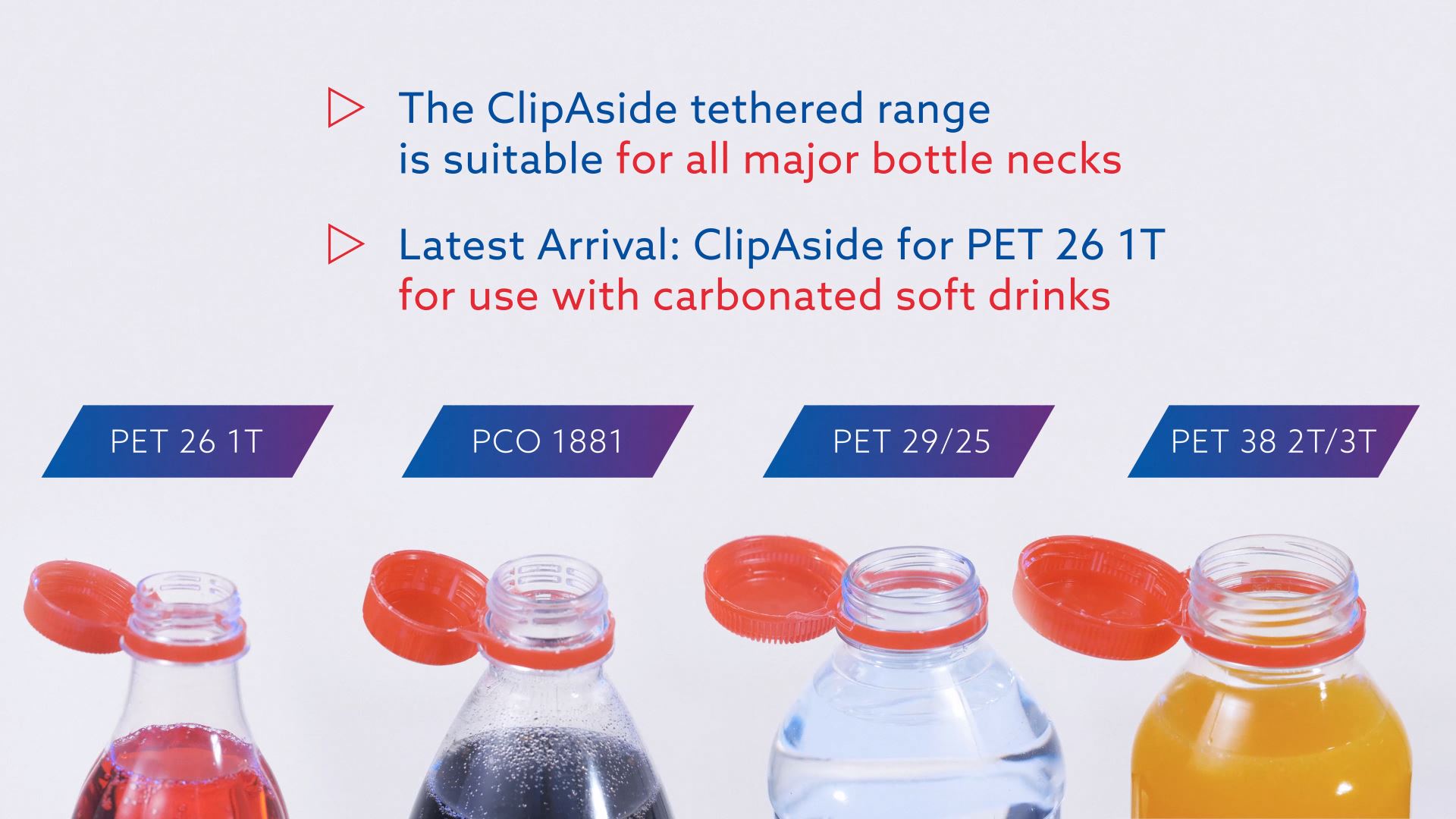

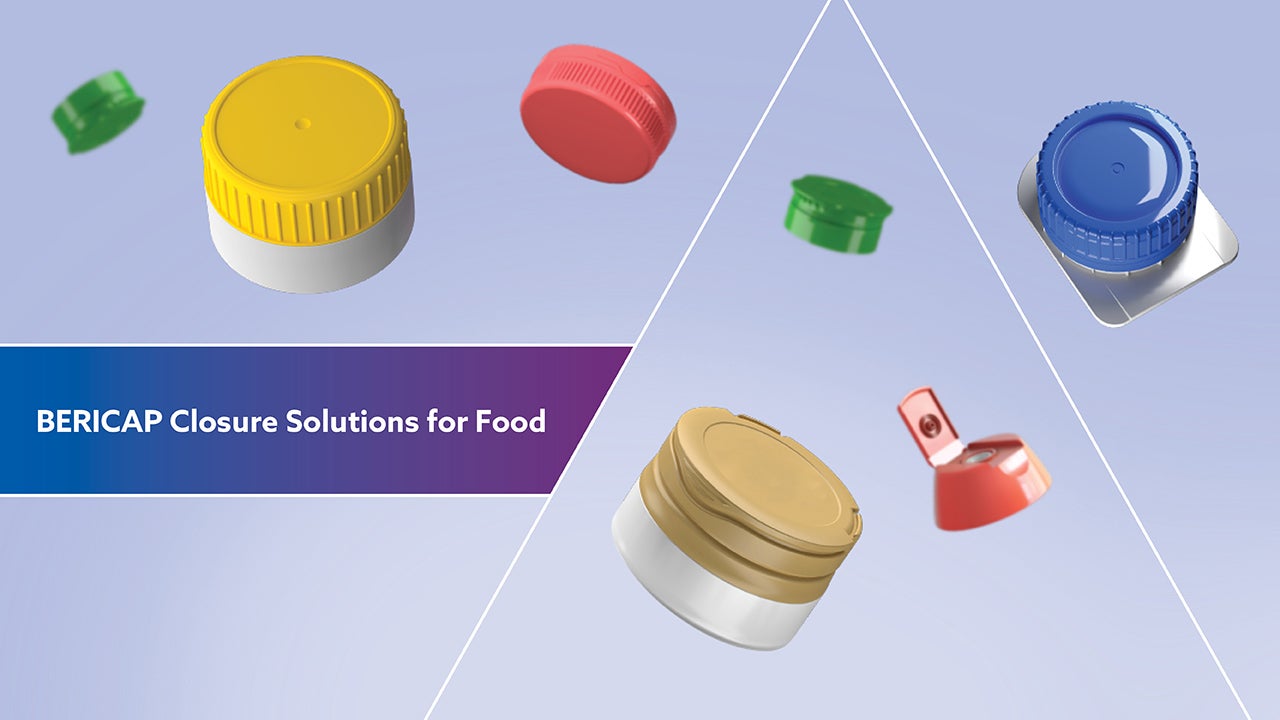

BERICAP’s extensive product portfolio includes closures for a variety of applications, from food and beverages to industrial applications. BERICAP provides closures for carbonated drinks, water, juices, energy drinks, and dairy products in the beverage sector, ensuring safe, tamper-evident packaging solutions. Regarding the food industry, we offer closures for oils, sauces, and syrups, all designed to protect product quality while providing a seamless user experience.

In addition to these products, BERICAP is a key player in the automotive, metal, and agrochemical sectors. We offer specialised closures with features such as counterfeiting protection, tamper-evidence, and ease of use, ensuring product security and peace of mind for consumers and businesses alike.

We understand that each market has unique needs and challenges, which is why BERICAP works closely with customers to develop customised solutions that meet their specific needs. We provide flexibility and innovation for standard applications and custom designs to ensure that our closures stand out in the marketplace.

Global presence and local expertise

With a team of over 4,200 employees worldwide, BERICAP boasts a team of over 4,200 employees globally and maintains a deep understanding of local markets. Our diverse team is united by a shared commitment to innovation, sustainability, and customer satisfaction. Each of our 30 production sites adheres to the same high-quality standards, ensuring that we can reliably meet the needs of our customers, no matter where they are located.