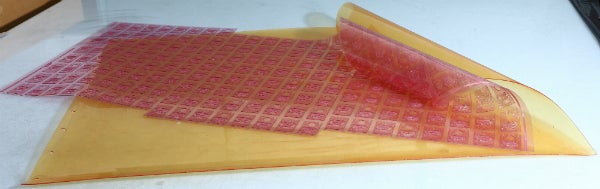

One of the most important exhibits by India’s largest global flexible packaging solution company Uflex at DRUPA 2016 will be Polymer Flexo Printing Plates.

The Digital Flexo-Plate Processing Set Up at Uflex offers sizable advantages impacting the quality and productivity of clients in terms of marked improvement in press-room, plate preparation, thereby reducing the overall cycle time. This efficiency can be ascribed to a unique combination of direct digital imaging and CYREL fast thermal processing.

The unique features of Uflex Flexo-Plate Processing Set Up are:

- (a) Highest Flexo image reproduction quality along with high-definition resolution of 5,080dpi

- (b) The Digital Plate Cutting Table enables giving a Staggered Plate Cut, which is as good as a Minimal Joint

- (c) One of its kind Wet Ink Proof Press for Flexo Plates enables to get a proof on the actual substrate using the same combination of Anilox rollers and Inks used by the printers

- (d) Ability to process plates as big as 42in x 60in. Narrow web plates can also be manufactured on the same set-up

- (e) World class machine manufacturing Laser Imagers from XEIKON Thermoflex and XEIKON Flexo Large and a complete plate processing workflow from Du Pont USA, Repro setup of Artpro and Deskpack from Esko Artworks

- (f) In-house creative designer team for preparing new artworks for any type of Stock Keeping Unit (SKU)

- (g) HD Flat Top Dot Technology for better dot reproduction that also imparts longevity to small dots

The flexible packaging major Uflex is all geared to exhibit best in class technology and equipment for print and cross-media solutions at the mega event, DRUPA.

Uflex will be in Hall No. 15 at Stand No. C 51.

Caption: Polymer Flexo Printing Plates.