Echo Instruments specialises in sensor technologies and measuring physical and chemical parameters in the occupation, safety, quality and process control of technological processes. We manufacture instruments for monitoring environmental emissions and different bio-reactions processes in aerobic and anaerobic states. In addition to standard production, we offer custom-made products, perform installation and provide expert advice on the correct selection of measuring principles and equipment.

Echo Instruments manufactures high-quality, innovative instruments, software and integrated systems for food industry, pharmacy, medicine, industry, biotechnology and environmental research.

Automatic system for quality control in packaging

BlistO2 is the first automatic pharmaceutical headspace oxygen analyser. This innovative measuring system is used for headspace oxygen analysis in pharmaceutical blister packs, vials and other products. The determination of the oxygen content within packages or pharmaceutical blister packs is of essential importance to ensure both filling quality and long-term storage stability.

In addition to automatic analysis, there is a new micro optical sensor built into the measuring system, which has plenty of advantages in comparison with classical electrochemical analysers. The optical sensor, based on the fluorescence measurement principle, does not need oxygen during analyses, which presents an advantage when performing long-time measurement of low oxygen concentrations in small places such as blister packs. With such an automatic unit it is possible to achieve high accuracy and high reproducibility.

Manual system for oxygen analysis in packaging

HandO2 is a manual needle type oxygen micro-sensor, which enables micro-invasive measurements with sensor tips smaller than 50μm. The most common use is for the determination of headspace and dissolved oxygen content in packages, for example in the pharmaceutical industry.

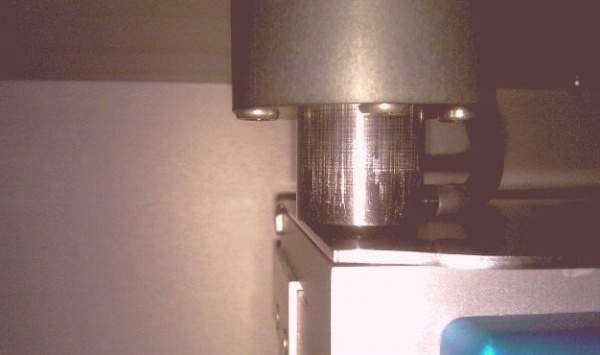

HandO2 is used for oxygen content measurements in pharmaceutical vials, packages and blisters. The measurements are made with an optical oxygen micro sensor mounted in the tip of the needle. The needle itself is 0.8mm wide, the sharpened tip is approximately 40mm long and it punctures the blister on the flat side.

Since BlistO2 represents an improvement in the accuracy and reproducibility of commonly used manual devices such as HandO2, we highly recommend the use of BlistO2. The advantages of HandO2 are its user-friendly navigation menu, automatic calibration of sensor and complete statistic data storage and report.

Gas analysers for packaging

Stationary gas analysers and gas analysis systems for laboratories and the packaging industry are suitable for direct monitoring of all clean gases, including corrosive and reactive gasses. Customers can combine different sensors, such as infrared, paramagnetic and electrochemical gas sensors. There are up to eight sensors in a 19in enclosure. Automatic calibration and configuration on demand are possible. Gas analysers for packaging operate stand-alone or PC-connected.

Gas mixing devices for packaging

Gas mixing devices for packaging simultaneously mix three or more gases in a balanced gas at different concentrations of dry corrosive gases: SO2, NO, NO2, Cl2, H2S in air or nitrogen. They enable precise control of gas mixing with high accuracy and repeatability, and accurate dilution of gasses prior to analysis. It is possible to order custom-designed instruments, for example the option of a built-in gas warning sensor when purging the housing with inert gases for safe operation with dangerous and flammable gases (maximum three channels). Gas mixtures used for analytical, production or industry application range from % down to ppm range.

We perform industry and R&D applications with high gas mixing demand, for dilution of sampling gas or preparing reference gas concentrations used in chemical laboratories, biotechnical, pharmaceutical, environmental field, chemical industry (reactors), biological tests (such as respirometers) and emission and immission measuring systems. It allows multi-point calibration of analysers, validation of gas instruments and mass flow controllers calibrated to a specific gas.

Respirometry systems: biodegradation of plastic packaging material

Echo Instruments manufactures respirometry systems that are used for conducting diagnostic tests and measuring and monitoring biodegradation of packaging materials in aerobic and anaerobic processes. These are useful for monitoring the biodegradation of different plastic material types at high temperature (maximum 60°C) and testing the stability of packaging material.

The systems are often used for the determination of compost maturity, BOD, toxicity and in food production (fermentation activity in wine production and milk industry). In different fields they are used for determination of microorganism activity (pharmacy and production of medicines), respirometry activity of small animals and biological activity of organisms (concentration of carbon dioxide in the expired air).