PreSens is a world leader in the field of chemical-optical sensors. It develops, manufactures and distributes sensor systems for biotech and pharma, food and beverage, scientific applications and medical devices. PreSens focuses on parameters which are essential for life: oxygen, pH and carbon dioxide. PreSens performs testing and manufactures in compliance with ISO 9001:2000 and EN ISO 13485:2003 and AC:2007.

PreSens’ product range is constantly expanding. We offer systems for:

- Dissolved oxygen measurement in gases and liquids

- Non-invasive on-line pH and oxygen measurement

- Oxygen ingress measurements in PET bottles and packages

- Headspace oxygen control

- Oxygen and pH sensors for single-use bioreactors

- Microsensors for pH and oxygen

- Process control in shake flasks

- Low-maintenance DO measurement for fermentation and bioreactor systems

- On-line oxygen and pH measurement in disposables like multiwell plates and plastic bags

Micro-invasive measurement and oxygen ingress measurement

Based on research activities started in the 1980s, PreSens Precision Sensing was founded in 1997 as a spin-off from the University of Regensburg, Germany. The company combines the vast experience of different researchers in the fields of electronic engineering and sensor development. Customer feedback has influenced our product development for several years and we can therefore serve your needs with validated measurement results.

Two of our key services with regard to packaging are:

- Micro-invasive measurement in packages

- Oxygen ingress measurement

Micro-invasive measurement in packages

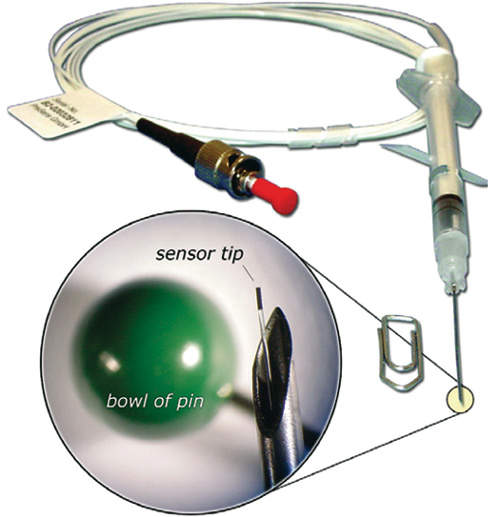

The determination of the oxygen content within packages or pharmaceutical vials is of essential importance to ensure both the filling quality and the long-term stability. With PreSens’ micro-invasive needle-type oxygen microsensors we offer a simple tool to determine oxygen concentrations in both the headspace and the liquid with fast response time (t90 < 1s in headspace).

The oxygen-sensitive tip of an optical fibre is protected inside a stainless-steel needle. The septum of the vial or package is pierced with the needle and the sensor is extended for measurement. As the measurement is made inside the package no error-prone sampling is necessary.

Transmitters for non-invasive needle-type oxygen microsensors

The transmitters to use with the non-invasive needle-type oxygen microsensors are the Microx TX3 and Microx TX3-trace: precise single-channel, temperature-compensated oxygen meters. They offer a detection limit of 1ppb dissolved oxygen. A PC is connected to run the easy-to-use software. In addition, analogue outputs and a trigger input are integrated.

Oxygen ingress measurement

A new non-invasive and non-destructive fibre-optic oxygen meter determines oxygen permeability of plastic bottles and containers. Trace oxygen concentrations down to 1ppb inside the package are measured. Ideal for assurance, production and quality control, this system incorporates the latest state-of-the-art chemical-optical sensor technology. Permeation rates can be confirmed without piercing the package or bottle.

Non-destructive fibre-optic oxygen meter

The sensing principle of the new fibre-optic oxygen meter is based on a fluorescence quenching method enabling oxygen measurements in a non-destructive way. A trace oxygen sensor spot is placed inside the transparent bottle or package and a fibre-optic cable is positioned on the outside. The luminescence lifetime of the oxygen-sensitive spot changes with the oxygen concentration and therefore acts as the oxygen-dependent parameter.

Single-channel, temperature-compensated oxygen meters

The ideal transmitters for this application are the Fibox 3 and Fibox 3-trace: precise single-channel, temperature-compensated oxygen meters. A PC is connected to run the easy-to-use software. In addition, analogue outputs and a trigger input are integrated.

Together with our partners we offer full service in Europe, the US and Asia. Please do not hesitate to contact us for any request concerning your customised solution.