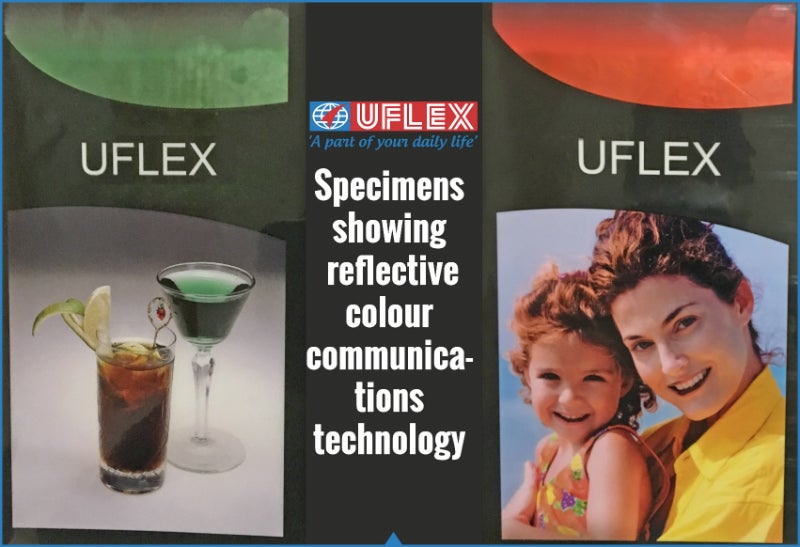

Getting a metallic sheen on a non-metallic substrate sounds rather uncanny, but owing to the reflective colour communication system offered by the Cylinders Business of India’s largest multinational flexible packaging materials and solution company Uflex, this has become a reality.

Metallic effect on non-metallic substrates can be achieved by reflective colour communication technology that works in combination of a Specialised Pre-Press Software and Special Laser Engraving Hardware.

This effect is attained by manufacturing a special Rotogravure Cylinder (may or may not be in place of a white cylinder) that uses normal transparent gold/ transparent silver inks or lacquer inks. The customised software ensures that the dots are precisely distributed throughout the design so as to produce a homogeneous metallic effect which shimmers better than printing done by some of the costliest metallic inks on metallic substrates / laminates.

Getting the same effect through specialised metallic inks can make conversion costs hit through the roof.

Some clear benefits of this technology are:

- Reduction of laminate cost for end customer: Converters and brands stand to benefit with a perfect metallic sheen on a two ply laminate instead of three or more substrates as long as a barrier layer is not required (compulsorily) by the product to be packed

- Reduced ink GSM: This special cylinder for metallic effect is manufactured as half tone image. Over and above this, if we eliminate the white printing cylinder (as white ink is opaque having solid pigment concentration) altogether, this arrangement translates to much less ink consumption which is a boon for the printer

- No additional capital expenditure: These cylinders work just as fine on the existing printing machines not requiring any modification or additional capital expenditure at the printer / converters’ end

- Cost-effective: This is an economical technology for augmenting a brand’s shelf appeal without the use of metallic inks that are extremely expensive

- Flexibility: This technology is adaptable for future substrates, inks and coatings

Commenting about the special reflective colour communication technology, Mr P K Agarwal, joint president cylinders business, Uflex Limited said: "This technology is a real shot in the arm for the convertors and helps them add value for their clients by enhancing the aesthetics of their packaging without using prohibitive metallic inks or metallic laminate for that matter. We are getting many enquiries for the special printing cylinder."

Talking further about this latest technology, Mr Ashok Chaturvedi, chairman and managing director of Uflex Limited, said: "With the help of the special reflective colour communication technology, we are adding immense value to the process of converting. Such progressive value addition throughout the chain eventually results in an aesthetically unique and functionally superior packaging.

"The Packaging/Converting Business Vertical at Uflex has already tried and tested this technology which makes us confident to offer this solution to converters outside Uflex. Being a fully integrated end to end flexible packaging materials and solution company we as a principle always test our products internally and market them only upon being adequately satisfied with the performance."