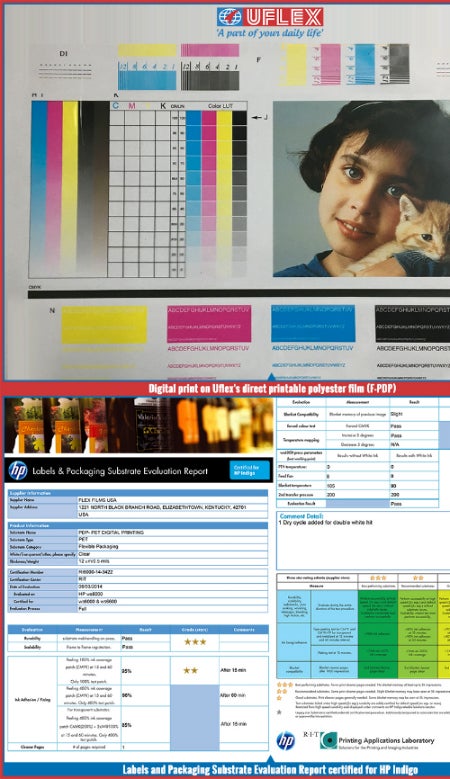

Uflex Launches HP Indigo Certified Digitally Printable Polyester Film, F-PDP

In contemporary times, digital printing is the name of the game given its ability to offer ultimate solutions for flexible packaging, labels and decorative printing segments.

The converting industry for long has been grappling with restricted availability of the right type of substrate supporting direct digital printing without prior priming /coating or surface treatment for that matter.

The main objective of any surface treatment method is to increase the energy of film’s surface for improving wet-out and adhesion of coatings, inks and adhesives used in converting process. Surface treatment of films/substrates may involve several techniques like corona discharge; flame treatment; priming and chemical etching. This could be an expensive proposition besides increasing the lead-time.

To alleviate this problem, India’s largest multinational flexible packaging materials and solution company Uflex Limited has launched a special polyester film, F-PDP with modified surface on one side while the other side remaining untreated. This film is digitally printable without any need for priming/ coating.

This film can be directly printed without requiring printing plates/ cylinders as in the case of conventional printing process. Additionally the film demonstrates good transparency; optical clarity; excellent machinability and dimensional stability besides offering excellent flatness and agile handling properties.

The polyester (PET) film F-PDP has been certified by Rochester Institute of Technology for digital printing by HP Indigo commercial and sheet fed presses.

There are a multitude of benefits associated with digitally printable PET films:

- Suitable for small run jobs particularly for new launch or re-launch of products

- Minimises lead-time at the converter’s end because no primer/ coating is required

- Gives excellent print results with high quality resolution for pictures and half-tone jobs using primary colors i.e. C,M,Y,K and white, giving results at par with conventional printing even on transparent substrates

- Option of special colors like Gold, Silver etc. can further impart depth in printing

Mr JK Sharma, AGM, Technical Service and New Product Development (Films), Uflex Limited talking about the benefits of digitally printable polyester film said: "Coating / priming or surface treatment of a film for enhancing its ink adhesion properties is a time consuming process needless to mention the additional costs that are involved. Our special F-PDP film is a perfect delight for convertors at a time when the entire world is moving towards just in time (JIT) deliveries minimising inventories. Polyester film suitable for direct digital printing has been a need gap.

"Other inherent advantages of Polyester film like the ability to render excellent print results; being tear-proof and crack resistant make it a suitable and preferred media for digital printing. Additionally Polyester is able to withstand high temperatures and remains stable and inert to many chemicals further enhancing its suitability for convertors."

Talking further about this specialised polyester film, Mr Pramod Sirsamkar, president Technical and New Product Development (Films), Uflex Limited said: "Depending upon the requirements of the ensuing converting process, we can offer F-PDP film in various thicknesses ranging from 10µ-50µ. The demand for this substrate is quite encouraging both in India, as well as overseas as a result of which we are manufacturing it at all our plants i.e. India, UAE, Poland, Egypt, Mexico and USA."

Mr Ashok Chaturvedi, chairman and managing director, Uflex Limited hailing the recent innovation said: "Digital printing spells out immense convenience for convertors in terms of economised costs; suitability for shorter print runs; less set up time compared to offset printing and unmatched print consistency among others. I am happy that Uflex has engineered a special polyester substrate that is perfectly receptive for digital printing without requiring any priming/ coating or special treatment."