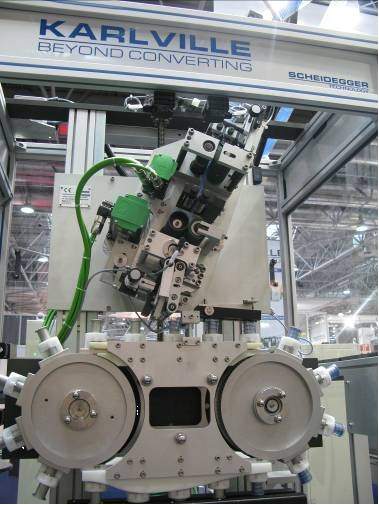

Karlville supplies high-performance machinery for shrink sleeve applications and converting, as well as adhesive packaging solutions. With facilities in North and South America, Europe and Asia, Karlville is globally positioned to provide products and support at competitive prices.

Having acquired Scheidegger in 2006 and CEFMA in 2008, Karlville has increased its portfolio of packaging solutions for shrink sleeve, tape handle and tape bundle applications. Karlville is trusted by a range of high-profile food and drink companies, including:

- Coca Cola

- Pepsi

- Nestle

- Schweppes

- Fanta

- Perrier

- Heineken

Tamper applicators

The Tampertec 1000 i is the most reliable, efficient and fastest tamper-evident application machine on the market. A servo motor reduces the machine’s footprint, allowing it to be integrated into existing labelling machines. This innovative design provides high accuracy, a compact line layout and minimal line conveyors. The sleeve can be placed accurately on to the bottle without the use of a Vbelt, plate or pre-shrink device.

Our new COMBITEC machine is an all-in-one tamper applicator, featuring a rejection system and an infrared shrink tunnel. Its compact design, servo motor and simple set-up makes it ideal for the pharma, food and beverage markets.

Full body shrink applicators

The SleevePro line comprises accurate, fast and smooth full body shrink applicators, with recent improvements including:

- Higher speed of up to 600cpm

- Increased registration accuracy

- Upgraded tension systems for smooth operation

- Continuous cutter motion technology that increases the life of moving components

- Faster format changes with saved recipes on touchscreen

- Smart fault-detection systems, such as bottle pitch differences, deformed bottles and splice detection

- IP connectivity for easy integration, remote maintenance and troubleshooting

Hot air shrink sleeve tunnel

For steam-sensitive applications, the Tornado tunnel is the ideal integrated electric shrinking system. The Tornado generates high-quality solutions similar to steam tunnels but with superior shrink appearance, for almost any container shape and without the use of steam. It provides the best solution for:

- Shrinking for heat or water-sensitive containers

- Shrinking for difficult shaped containers

- Eliminating after-shrink wrinkles

- Eliminating the need for steam boiler infrastructure

- Saving space and energy

- Minimising mechanical maintenance

Pouch converting machines

The new multiformat pouch converting machine comprises the versatile KSG multiformat pouch machine and two available modules. Module I produces single and dual gusset shaped pouches with a front-face dispensing spout, while Module II makes side gusset pouches with a front-face pour spout. Each roll-away, quick-change module comes with a vibratory bowl feeder, rotary spout application system, servo motor, draw roller, electronics and tooling.

Module I features:

- Multiple spout configurations for market changing applications

- Ergonomic carry handle

- Fast chill and frozen drink capabilities

- 1.5l-3l applications

- One-way dispensing valve that extends product life

Module II features:

- Simple flat seal for spout allows for optimum leak-resistant performance

- Ergonomic carry and pour handles

- Fabrication of pouch with a single web to minimise seal areas

- 1l-20l applications

- Ideal for institutional packaging applications

Environmentally sustainable pouches

Compared with glass and plastic, our new package is designed with an 80% reduction in total carbon footprint, an 80% increase in transportation energy savings and a significant decrease in waste volume. The recycled pouches are fabricated from 100% PE materials, making Karlville’s sustainable pouches the ideal eco-friendly option.

Adhesive packaging systems

The CEFMAHANDLE range comprises 20 different carry-handle application machines for bulky items such as packs of drinks, paper and pet food. With production speeds from five to 200 handles per minute, CEFMAHANDLE equipment can be easily adjusted to handle packages of all dimensions.

The CEFMAPACK range includes patented and efficient machines for bundling multi-packs, using printed or neutral adhesive tape. These economical and ecological systems can achieve savings of up to 50% on the costs of equipment, operation and consumables. With production speeds from 15 to 60 packs per minute, CEFMAPACK equipment works for all types of products.