Packsize is a leading international provider of automated, right-sized packaging on demand solutions for a wide range of industries, delivering the most efficient and sustainable specific processes to our customers. We are committed to providing Smarter Packaging for a Healthy Planet by achieving economic and ecological benefits for and with our customers ‒ deploying our eco-friendly packaging concept reduces our clients’ overall carbon footprint significantly.

Companies deploying Packsize on their premises benefit from significantly lower material, labour and freight costs, as well as increased process efficiency and productivity, while protecting the environment with every box created. As a trusted partner and advisor, Packsize unlocks hidden cost-saving and productivity potential in our customers’ warehouses and designs custom packaging process flow solutions together with them.

As a global technology company, Packsize operates two R&D and manufacturing facilities ‒ one in Louisville, Kentucky, and a legacy facility in Enköping, Sweden. From our global headquarters in Salt Lake City, Utah, we oversee markets in the Americas, while our European head office in Herford, Germany, serves European markets.

Packaging as a Service

Packsize offers Packaging as a Service, which means jointly designing, implementing and optimising innovative packaging process flows, tailored to our customers’ needs and targets. Packaging as a Service consists of hardware systems, software tools, materials, and best-in-class pre-sales and post-sales services to achieve flawless intralogistic process flow in our customers’ operations. Every product and order gets a custom-sized shipping box designed to take up the least space possible.

Packaging as a Service represents much more than just hardware, software, corrugated cardboard or boxes. It is a comprehensive service and finance agreement (no risky upfront investments necessary) that provides process design, technology and continuous operational flow, taking connectivity, process flow and optimisation into account.

Packsize develops technology, automation, innovation and operational services, involving the most reliable yet cost-competitive corrugated supply chain expertise. We create value on our customers’ premises by process optimisation to jointly achieve more throughput, efficiency, productivity, customer satisfaction and sustainability.

Innumerable companies and industries can benefit from Packsize technology, processes and services, such as the manufacturing sector (e.g. medical devices, household appliances, tools, lighting, toys), logistic service providers (3PL), retail, e-commerce and its fulfilment, furniture firms, or printing agencies.

Packaging Process Flow

Packaging process flow could ideally be defined as a fully automated, intralogistic process from high-bay shelf picking to the shipping of ordered items ‒ aiming for the highest possible throughput and productivity through world-class Overall Equipment Effectiveness (OEE), while driving any unnecessary cost out.

Optimised packaging process flow requires a detailed analysis of comprehensive warehouse processes together with our customers from various industries. We work alongside our clients to design, implement and optimise innovative process solutions tailored to their needs and targets. Optimised process flow reduces material consumption, manual labour, transport costs and carbon dioxide (CO₂) emissions, accelerating the path to a more sustainable future.

Right-sized Packaging on Demand

Packsize leads with automated, sustainable and correctly sized Packaging on Demand solutions. On our customers’ premises, we individually create the smallest possible corrugated transport box for every product or combination of products, for every order, in time for when the shipment needs to be executed. These packaging solutions help reduce intralogistic costs while improving operational efficiency, product protection during transport, consumer satisfaction when unwrapping, and environmental impact.

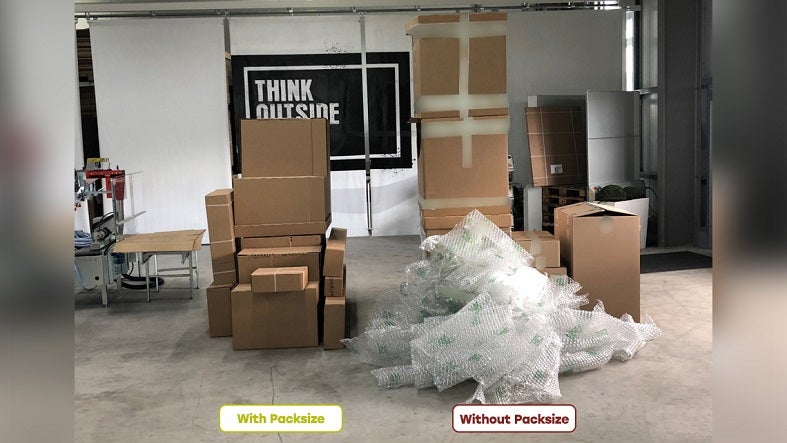

Sustainability was and will always remain an underlined key driver of our offering. Packsize processes make every box 40% smaller on average by ‘taking air out’. This approach reduces cardboard by 25% and void fill by 60%, with this usually being made of plastic. Smaller boxes mean that more boxes fit into one truck, so fewer trucks need to be on the streets.

All in all, this relieves the environment significantly by reducing CO₂ emissions. Every 100 square kilometres of corrugated deployed reduces greenhouse gas emissions by 25t (the average adult European citizen causes annual CO₂ emissions of about 8.5t).

Full Automation vs. Full Flexibility

Packsize offers the widest range of flexible, automated and sustainable corrugated packaging solutions directly at production or logistic facilities ‒ always with a keen eye on packaging process flow and system integration.

Since every product and order gets its specific minimally sized shipping box, Packsize helps you to pack essentially everything ‒ from a tablet computer to garden house profiles and entire sofas. The Packsize solution offering ranges widely from full automation at highest speed (1,000 packages an hour ready to be shipped) to full flexibility in terms of product and box sizes (7m-long boxes or 250kg loads) and also box designs (edge protection, container/lid applications).

Everything you need can be packed with Packsize solutions. We Fit Everything You Need.