In an era where medication management plays a vital role in healthcare, the advent of multi-dose packaging systems has emerged as a transformative solution.

By revolutionising the way medications are packaged and dispensed, these innovative systems are streamlining delivery processes, enhancing patient compliance and optimising overall efficiency.

Discover the immense potential of multi-dose packaging as we delve into its game-changing benefits for the pharmaceutical industry.

What is multi-dose packaging?

Multi-dose packaging refers to a packaging format or system designed to contain multiple doses of a medication or product in a single package.

It is commonly used in the pharmaceutical industry to provide a convenient and organised way of dispensing and administering medications over an extended period.

The multi-dose packaging system is a comprehensive approach to packaging that involves the design, production and distribution of containers or packages capable of holding multiple doses of a product.

This system typically includes specialised packaging materials, such as blister packs or strip packs, along with labelling and instructions for use.

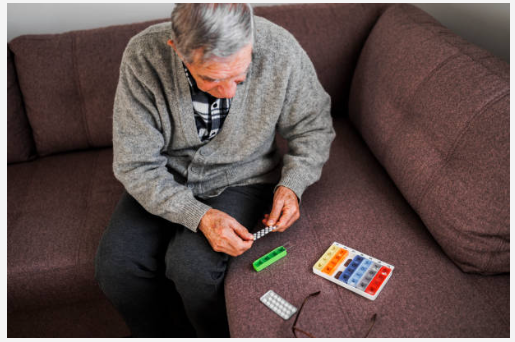

Gone are the days of juggling multiple pill bottles and struggling to remember complicated dosing schedules. With the advent of multi-dose packaging, medications are conveniently organised into pre-filled compartments, simplifying administration, improving adherence and enhancing patient outcomes.

This innovative solution streamlines the medication-taking process and offers a range of benefits for healthcare providers and caregivers, ushering in a new era of efficiency and patient-centred care.

Benefits of multi-dose packaging

Multi-dose packaging and the corresponding packaging systems offer numerous advantages, including:

Convenience: Multi-dose packaging eliminates the need for measuring or counting individual doses each time they are required. It provides pre-determined doses that are easily accessible, making it convenient for patients, healthcare professionals and caregivers.

Improved medication adherence: With multi-dose packaging, medications can be organised and labelled according to specific dosing schedules, such as daily or weekly regimens. This helps patients follow their prescribed medication routines more easily, reducing the risk of missed doses or incorrect administration.

Enhanced safety: Multi-dose packaging reduces the chances of medication errors. Clear labelling and packaging design ensure that patients can easily identify the correct medication, dosage and administration instructions. This can be especially beneficial for individuals who are managing multiple medications.

Protection and longevity: Multi-dose packaging often includes features like individual compartments or blister packs that protect the medication from moisture, light and air. This can help maintain the stability and effectiveness of the product for a longer period.

Portability: Multi-dose packaging systems are designed to be compact and easily transportable, allowing patients to carry their medications conveniently during travel or daily activities. It reduces the need for carrying multiple medication bottles or packages, promoting mobility and independence.

Cost-effectiveness: By bundling multiple doses in a single package, multi-dose packaging can help reduce packaging waste and potentially lower costs associated with medication dispensing and distribution.

The multi-dose packaging system market

According to a recent report, the global Multi-Dose Packaging System market is projected to experience significant growth in the coming years.

Key players in the market

The global multi-dose packaging system market includes several key players driving the industry. Some prominent companies in the market are Omnicell, McKesson Corporation, Becton, Dickinson and Company, Parata Systems, RxSafe, ARxIUM, Talyst, TCGRx and Pearson Medical Technologies, among others. In 2022, the top three vendors accounted for a significant portion of the revenue in the market.