UK-based Denhay Farms has integrated Ravenwood’s linerless technology to automate its bacon sleeve packaging operations.

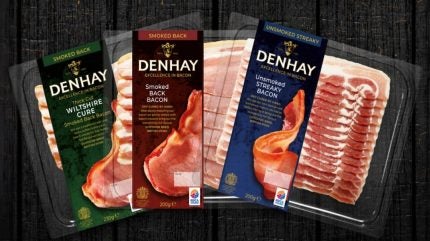

Established in 1952, Denhay has been crafting bacon for approximately 30 years. Its products are available through domestic retailers Waitrose and Sainsbury’s, as well as Ocado and Amazon Fresh.

Denhay has installed two Ravenwood Nobac 5000 linerless applicators, streamlining its production processes and reducing reliance on manual labour.

The company has also joined forces with ProPrint Group, a domestic provider of linerless printing, to help produce the new linerless sleeves.

The switch to linerless technology aligns with Denhay’s strategy to enhance staff welfare and optimise spending.

Denhay implemented the fully automated labelling system across all its own-label sliced bacon products, including the Spoilt Pig brand and wholesale catering packs.

In addition to enhancing packaging efficiency, the technology has reduced storage and shipping space due to the compact nature of linerless reels compared to traditional manual sleeves.

Before this change, employees reportedly dedicated long hours to repetitive manual sleeving tasks. With the transition to linerless, staff now have more time to concentrate on other aspects of production.

During the transition, Denhay said it aimed to maintain the appearance and feel of its original cardboard sleeves.

The company stated that the new sleeves, supplied on a roll and cut to size by the applicator, are designed to meet these aesthetic standards.

The lack of backing paper offers a sustainable solution, according to Denhay.

Denhay Farms managing director Jim Loescher said: “We’re absolutely thrilled with how seamlessly the linerless applicators and our new linerless sleeves have integrated into our production process.

“The machines have transformed our labelling operations, making it faster and more efficient, while the sleeves provide a premium, high-quality solution that perfectly complements Denhay’s brand.”