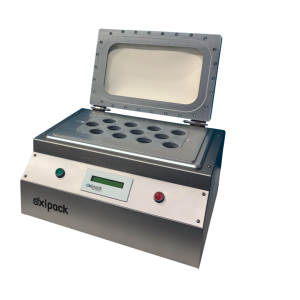

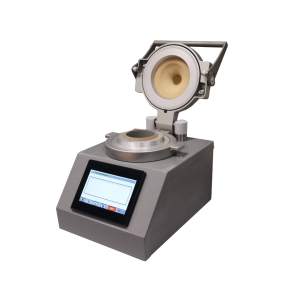

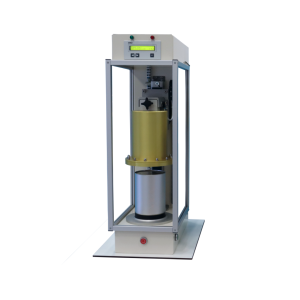

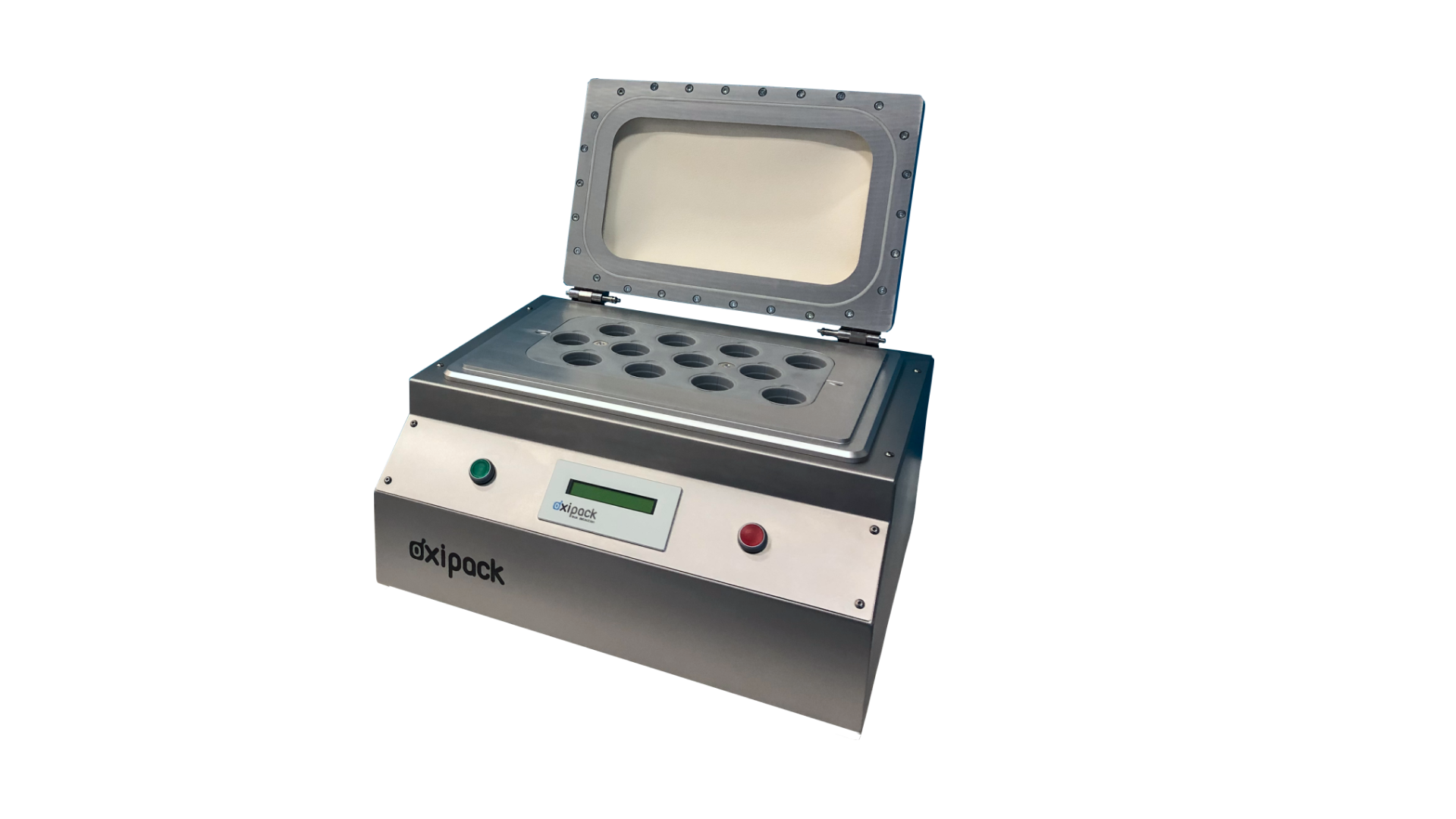

Stationary Leak Tester XS (SLT XS)

Perfect for smaller rigid packaging, the SLT XS offers precise leak detection using Oxipack’s vacuum decay method (ASTM F2338). The system’s compact design and customizable membrane make it ideal for testing small packages like pods or capsules.

Key Features

- Non-Destructive Testing: The SLT XS detects leaks without compromising the packaging, ensuring that tested products remain intact.

- Vacuum Decay Technology: This technology is trusted for its precision, detecting even micro-leaks that might otherwise go unnoticed. The SLT XS creates a vacuum within the test chamber, then monitors for any pressure changes, indicating the presence of leaks.

- Compact and Flexible Design: With a smaller footprint compared to other testers in the SLT series, the SLT XS is designed for testing smaller, rigid packaging types. This makes it ideal for pharmaceutical and cosmetic packaging like vials, ampoules, and jars.

- Fast and Accurate: Offering quick results within 30 seconds, the SLT XS delivers an immediate pass/fail indication through its intuitive green/red light system. It also displays the leakage rate for added insight into the severity of the leak.

- Multiple Testing Applications: The SLT XS is versatile, able to test various rigid and semi-rigid packaging, including modified atmosphere packaging (MAP), making it suitable for products in food, pet food, and medical industries.

- User-Friendly Operation: Designed for ease of use, the SLT XS requires minimal setup and provides straightforward operation through its digital interface. The test results are displayed in real-time, making it simple for operators to ensure packaging integrity.

Technical Specifications

- Dimensions and Weight: 475 x 425 x 333 mm (L x W x H), 22 KG

- Materials: Stainless steel, Anodised aluminium, Polycarbonate, Rubber

- Power Supply: 100 – 230V 50/60HZ

- Air Supply: > 5.5 – < 8 bar

- Compliance and IP Rating: CE IP20

- Test Block Size: 200 x 250 x 425 mm (L x W x H)

- Leak Detection Method: ASTM F2338

- Minimum Leakage: > 0.9 cm3/min

- Maximum Testing Capacity: 2P/M

- Connections: USB/Ethernet export, 24VDC logic (free programmable)

- Packaging Type and Size: Rigid Package MAP Cup Tray Pods

Benefits

- Increased Quality Control: The SLT XS helps companies reduce waste and save costs by ensuring that only leak-free products reach the market. This aligns with Oxipack’s commitment to sustainability and zero waste.

- Versatility: Suitable for a wide range of industries, from pharmaceutical packaging to food production, the SLT XS delivers the precision and reliability required for high-stakes products.

- Compact Efficiency: Despite its small size, the SLT XS is powerful, delivering the same robust leak detection performance as its larger counterparts, making it ideal for businesses with limited space.

Applications

- Pharmaceutical Packaging: Ensure the integrity of vials, ampoules, and other small rigid packages without risking contamination.

- Cosmetic and Personal Care: Protect sensitive products in jars and bottles from air and moisture leakage.

- Food Industry: Guarantee leak-free packaging for modified atmosphere packaging (MAP) products such as pouches and trays.

The SLT XS is an efficient, reliable solution for companies that require top-tier packaging leak detection. Its non-destructive testing method and vacuum decay technology provide peace of mind that your products meet the highest standards of quality and safety.